- Home

-

- TF Integrated Workstation

- TT Integrated Station

- TS Single-Person Station

- TO Single-Person Station

- Advanced Office Table

- Manager Table

- Odette Conference Table

- Lifting White Board

- Lifting Podium

- Working Port

- Zen Standing Desk

- Lifting Coffee Table

- Home Standing Desk

- Nature Standing Desk

- Invictus Gaming Desk

- Study Desk

-

-

- Electric Hospital Bed

- Image Equipment

- Examination Bed/Clinic Bed

- Operation Table and Chair

- Infant Incubator

- Independent Weighing System

- Home Care Bed

- Patient Lift

- Wheelchair

- Toilet Lift

- Bath Lift

- Shower Trolley

- Smart Rollator

- Ophthalmic Workstation

- Treatment Chair

- Facial Chair

- Traction Table

- Massage Chair

- OT Training Equipment

- Stand-up Application

- Rehabilitation Robot

-

-

- Photovoltaic Application

- Photothermal Application

- Energy Storage Container

- Tractor

- Seeder

- Fertilizer Spreader

- Harvester

- Rotary Cultivator

- Climate Control System

- Automatic Feeding System

- Excavator

- High Altitude Work Platform

- Garbage Truck

- Street Sweeper

- AMR Automated Guided Vehicle (AGV) and Autonomous Mobile Robot (AMR)

- Forklift Accessories

- Palletizing Collaborative Robots

- Packaging Machine

- Mobile Light Tower

-

-

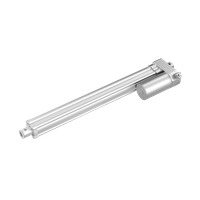

Complete Guide to Linear Actuator Systems For 2025

Views: 0 Author: Site Editor Publish Time: 2025-06-11 Origin: Site

A linear actuator system is a mechanical solution that converts rotary motion into linear movement, enabling precise positioning and motion control across various applications. Whether it's for medical equipment, industrial automation, or smart furniture, linear actuators provide the push or pull needed to move or lift objects smoothly and safely.

Modern linear actuator systems are essential in industries that demand quiet operation, efficient power use, and precise control. From automated standing desks to robotic arms, these systems are powered by combinations of electric motors, gearboxes, screws, belts, and control electronics—making them the core of many electromechanical solutions.

1. Understanding Linear Actuator Components and Parts

A well-functioning linear actuator system is made up of several key linear actuator components. Each part plays a vital role in delivering smooth, controlled motion:

Motor (DC, AC, or linear servo): The heart of the actuator, providing the necessary torque.

Gearbox: Used to adjust speed and increase force output.

Lead screw or belt mechanism: Converts the motor’s rotary motion into linear motion. These include the linear screw actuator or the belt driven linear actuator.

Guides and bearings: Support movement while reducing friction.

Housing and seals: Protect internal linear actuator parts from dust and moisture.

Limit switches and sensors: Ensure safe operation and precise positioning.

All linear actuator components must work together seamlessly to provide accurate, repeatable motion. At Jiecang, each linear actuator part is manufactured to high standards, ensuring durability and long service life.

2. Popular Types of Linear Actuator Systems

There are several types of linear actuator systems, each suited to different performance requirements and use cases:

Belt Driven Linear Actuator

A belt driven linear actuator uses a toothed timing belt to move the carriage. It is ideal for high-speed, long-stroke applications, such as in logistics automation, pick-and-place machinery, or CNC systems. Benefits include:

Fast travel speeds with low noise

Longer travel lengths

Lower cost for extended range applications

Linear Screw Actuator

A linear screw actuator uses a ball screw or lead screw to provide highly accurate linear motion. Common in electric hospital beds, height-adjustable workstations, and industrial presses, it offers:

High positioning accuracy

Strong load-bearing capacity

Smooth and silent operation

Linear Actuator 24V

A linear actuator 24V operates using 24-volt DC power, which is commonly used in mobile and battery-powered devices. These actuators are safe, energy-efficient, and versatile, suitable for:

Smart home furniture

Automotive systems

Solar tracking systems

Linear Servo

A linear servo system integrates a servo motor for advanced feedback and high-precision motion control. These are used in robotics, medical imaging devices, and automation systems that require dynamic performance and accuracy.

3. Choosing the Right Linear Actuator Kit

A linear actuator kit like an electric hospital bed, bath lift and shower trolley and so on, typically includes the actuator unit, control box, remote or wired switch, brackets, and installation hardware. For engineers, OEMs, and DIY enthusiasts, selecting the right kit depends on:

Load capacity requirements

Stroke length and speed

Control needs (manual, wireless, programmable)

Power supply compatibility (e.g., linear actuator 24V)

Whether you're integrating a linear screw actuator into a hospital bed or using a belt driven linear actuator for factory automation, Jiecang offers modular linear actuator kits designed for fast and efficient implementation.

4. Applications of Linear Actuator Systems

Linear actuator systems are widely used across industries due to their reliability, flexibility, and low maintenance. Some major application areas include:

Smart Furniture: Sit-stand desks, TV lifts, recliner mechanisms using linear actuator 24V for quiet, safe movement.

Healthcare: Patient lifts, surgical tables, and treatment chairs utilize linear screw actuators for precise, load-bearing motion.

Industrial Automation: Conveyor belts, packaging machines, and robotics often rely on belt driven linear actuators and linear servo systems for synchronized motion.

Agriculture & Solar: Solar panel trackers, greenhouse ventilation systems powered by efficient linear actuator kits.

Automotive: Power seat adjustments, electric tailgates, and automatic window regulators use linear actuator parts with compact design.

5. Installation and Maintenance Tips

Installing a linear actuator system involves careful planning and integration of all linear actuator components. Key installation steps:

Ensure proper alignment to avoid stress on the actuator.

Secure brackets firmly to prevent vibration.

Connect to the appropriate control system—especially for linear servo or smart linear actuator 24V units.

Maintenance Tips:

Periodically inspect linear actuator parts for wear or damage.

Lubricate lead screws and guides in linear screw actuators.

Replace worn belts in belt driven linear actuators.

Keep electronics dry and free from dust.

6. Why Choose JIECANG Linear Actuator Systems?

JIECANG is a global leader in linear actuator systems, offering cutting-edge solutions with certified quality and strong customization capabilities. Our products include:

High-precision linear servo systems

Durable belt driven linear actuators

Medical-grade linear screw actuators

Modular linear actuator kits for smart furniture and industrial automation

Energy-efficient linear actuator 24V solutions

With advanced manufacturing, R&D capabilities, and responsive customer support, Jiecang ensures seamless integration and long-term reliability in every actuator solution.

Conclusion

Choosing the right linear actuator system is essential for building high-performance, efficient, and safe automation solutions. From advanced linear actuator components to complete linear actuator kits, Jiecang provides tailored systems to meet the evolving needs of healthcare, industry, furniture, and robotics.

Explore our full range of linear screw actuators, belt driven linear actuators, and linear servo systems to elevate your project today.

Linear Actuator System FAQs:

1.What does a linear actuator do?

A linear actuator actuates - or moves - in a straight line. The primary reason for designing a linear actuator into a system is to address the need to accurately move a payload in a linear fashion, rather than a rotary one. The operation of a Linear actuator is simple.

2.What happens when a linear actuator fails?

When an actuator fails, it could result in catastrophic explosion, spill, chemical release, property damage, power loss, environmental contamination, injury, or even loss of life. Actuators trigger immediate shutdowns which could result in costly production downtime.

3.What is the purpose of the actuator?

An actuator is a device that converts energy into some kind of "operation", such as linear movement, rotation, or bending. In addition to electricity, the input energy comes in a variety of forms, such as air (pneumatic) or oil (hydraulic) pressure, magnetic force from electromagnets, steam, and heat.

Related Articles

QUICK LINKS