- Home

-

- TF Integrated Workstation

- TT Integrated Station

- TS Single-Person Station

- TO Single-Person Station

- Advanced Office Table

- Manager Table

- Odette Conference Table

- Lifting White Board

- Lifting Podium

- Working Port

- Zen Standing Desk

- Lifting Coffee Table

- Home Standing Desk

- Nature Standing Desk

- Invictus Gaming Desk

- Study Desk

-

-

- Electric Hospital Bed

- Image Equipment

- Examination Bed/Clinic Bed

- Operation Table and Chair

- Infant Incubator

- Independent Weighing System

- Home Care Bed

- Patient Lift

- Wheelchair

- Toilet Lift

- Bath Lift

- Shower Trolley

- Smart Rollator

- Ophthalmic Workstation

- Treatment Chair

- Facial Chair

- Traction Table

- Massage Chair

- OT Training Equipment

- Stand-up Application

- Rehabilitation Robot

-

-

- Photovoltaic Application

- Photothermal Application

- Energy Storage Container

- Tractor

- Seeder

- Fertilizer Spreader

- Harvester

- Rotary Cultivator

- Climate Control System

- Automatic Feeding System

- Excavator

- High Altitude Work Platform

- Garbage Truck

- Street Sweeper

- AMR Automated Guided Vehicle (AGV) and Autonomous Mobile Robot (AMR)

- Forklift Accessories

- Palletizing Collaborative Robots

- Packaging Machine

- Mobile Light Tower

-

-

Comprehensive Guide to Linear Actuators

Views: 0 Author: Site Editor Publish Time: 2025-09-25 Origin: Site

In modern automation and smart devices, linear actuators play a vital role. They convert energy into precise linear motion, driving a wide range of applications from industrial machinery to smart home devices. Whether electric, pneumatic, or hydraulic, choosing the right actuator not only affects equipment performance but also determines system reliability and efficiency. This guide will give you a comprehensive understanding of the types of linear actuators, key technical parameters, application scenarios, and selection tips, helping you make informed decisions and achieve optimal application results.

1. What is a Linear Actuator?

Simply put, a Linear Actuator is an electromechanical device that converts energy into linear mechanical motion. Its core function is to transform input energy—whether Electric Power, Hydraulic Pressure, or Pneumatic Pressure—into controllable linear pushing, pulling, or positioning actions (Linear Motion / Positioning), thereby driving mechanical systems to perform tasks as intended.

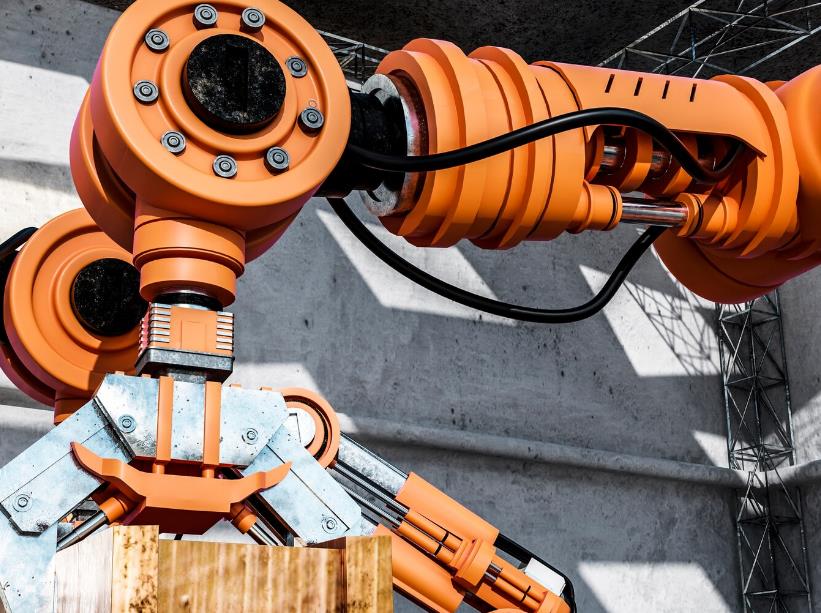

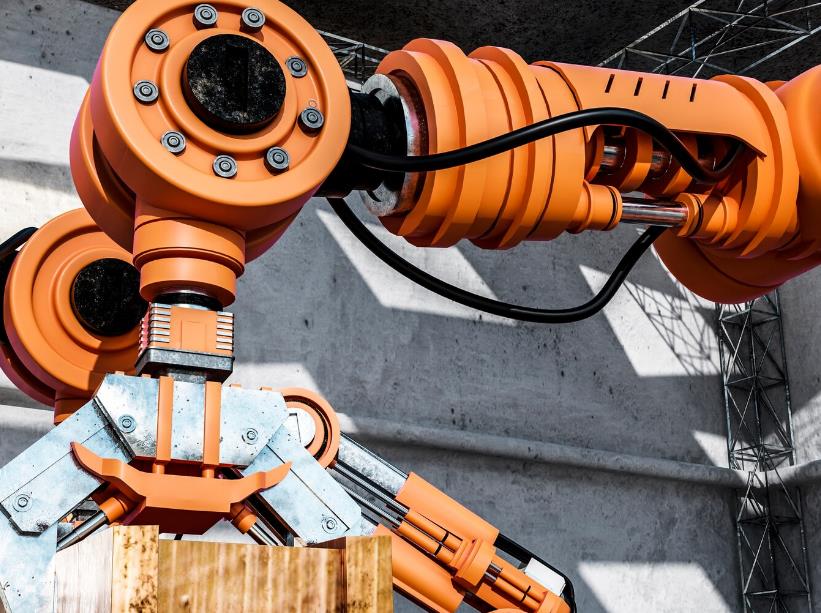

Unlike Rotary Motion, linear motion occurs along a straight path, making it easier to achieve High Precision Control (Precision Control) and Accurate Positioning. Therefore, in Industrial Automation, Precision Machinery, and Smart Systems, linear actuators are widely used. For example, robotic arms (Robotic Arm) on production lines can use linear actuators to perform gripping, handling, or assembly operations; in pipeline systems, actuators can control Electric Valves to regulate fluid flow; in Home Automation, they are applied in Automatic Doors, Height-Adjustable Desks, or Motorized Curtains, enabling convenient automated control.

In addition, linear actuators can not only perform single push-pull actions but also achieve Continuous Precision Positioning. Combined with Position Sensors / Feedback Sensors and a Control System, actuators can adjust movements based on real-time feedback to achieve Closed-Loop Control, ensuring smooth, reliable, and repeatable mechanical actions.

In summary, a linear actuator is a key electromechanical device that efficiently converts energy into Controllable, Accurate, Repeatable Linear Motion, making it an indispensable core component in modern industrial automation, robotic systems, and smart devices.

2. Working Principle of Linear Actuators

In industrial automation and mechanical equipment, the principle of linear actuators is fundamental knowledge. A linear actuator is a device that converts energy into controllable mechanical motion, allowing equipment to push, pull, or precisely position. Different types of actuators have different input methods and operating characteristics.

There are three main types of linear actuators:

Electric Linear Actuators:

Take current or voltage as input, use a motor to drive a screw, gear, or other transmission mechanism to achieve linear motion. They are suitable for scenarios requiring precise displacement control, such as automated production lines or precision machinery.

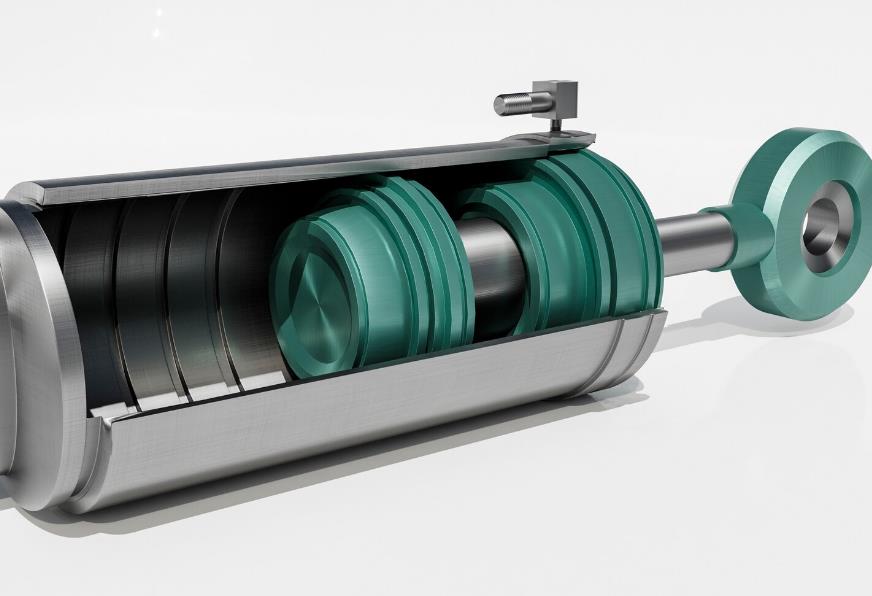

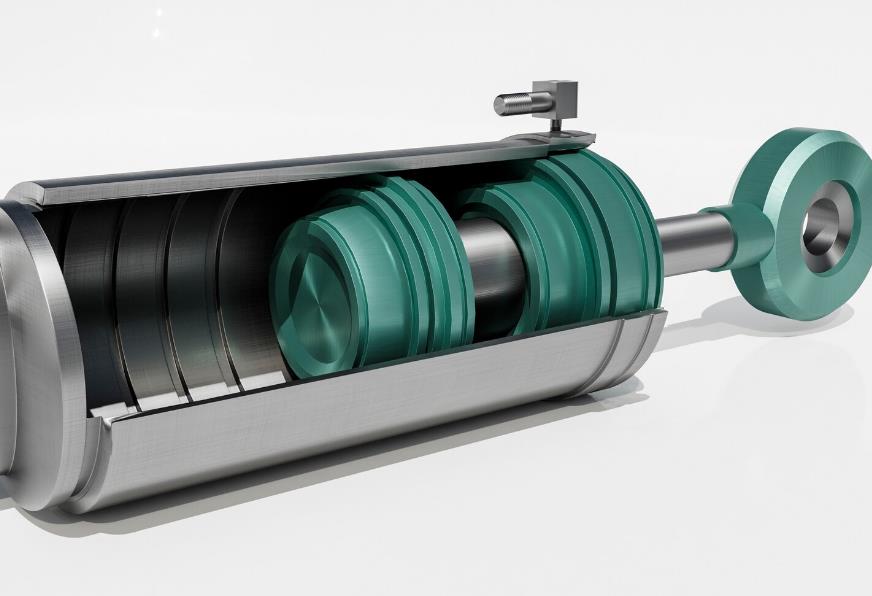

Hydraulic Actuators:

Use incompressible liquid pressure to convert fluid energy into mechanical force, providing high thrust. They are commonly used in industrial machinery, heavy-duty equipment, and construction machinery. Their advantages include smooth, powerful motion and high load capacity.

Pneumatic Actuators:

Feature fast response. They achieve motion by using compressed air to push pistons or rods, suitable for lightweight, high-speed operations such as automated assembly, sorting machines, or packaging equipment.

After understanding the basic types and operating characteristics of electric, hydraulic, and pneumatic linear actuators, we need to look deeper into how they work. Regardless of type, actuators always consist of several core components: Power Supply, Actuator Body, Mechanical Load, and Controller. These components work together to convert input energy effectively and precisely into mechanical action.

Power Supply:

The power supply provides energy to drive the actuator. In electric actuators, the motor is the core for achieving mechanical motion. The power supply delivers electricity to the motor, whose rotation drives the screw, gear, or transmission mechanism, precisely converting electrical energy into linear motion. This process determines the actuator’s thrust, speed, and positioning accuracy, and is key to smooth system operation. Inverters or controllers further regulate motor input, making movement more stable and reliable. Although hydraulic actuators rely on hydraulic pumps and pneumatic actuators rely on compressed air, the motor’s role in electric actuators is the most prominent. A stable and reliable power supply and a high-efficiency motor are fundamental to ensuring fast response and precise motion, directly affecting performance and lifespan.

Actuator Body:

The actuator body is the core part where energy is converted into linear motion. It usually contains pistons, screws, gears, or other transmission mechanisms, which determine output accuracy, speed, and load capacity. The design of the actuator body directly affects motion stability and efficiency.

Mechanical Load:

The mechanical load is the target device driven by the actuator, such as doors, valves, slides, or robotic arms. The weight and resistance of the load determine the required thrust and speed of the actuator, as well as the overall stability and service life of the system.Controller:

The controller regulates input signals so the actuator operates at preset speed, position, and force. In closed-loop systems, the controller also adjusts actions based on sensor feedback in real time, ensuring precise and stable linear motion while preventing overload or impact.3. Types of Linear Actuators

Linear actuators can be divided into three main categories based on driving energy and working principles: Electric Linear Actuator, Hydraulic Linear Actuator, and Pneumatic Linear Actuator. Each has unique features, applications, and internal structures.

1.Electric Linear Actuator

An electric actuator uses a Motor to drive screws, gears, or belts, precisely converting electrical energy into linear motion. It offers high precision, easy control, and simple maintenance.

Electric linear actuators can be further divided into:

Lead Screw / Ball Screw Actuator:

Moves linearly through a screw and nut, suitable for medium-small loads and high-precision applications.

Rack and Pinion Actuator:

Converts motion through gear-rack engagement, suitable for long-stroke, heavy-load applications.

Belt-Driven Actuator:

Uses synchronous belt transmission for fast, long-stroke linear movement, often applied in lightweight automation equipment.

2.Hydraulic Linear Actuator

A hydraulic actuator uses a Hydraulic Pump and liquid pressure to drive a piston, achieving high-thrust linear motion. It is suitable for heavy loads and continuous operation.

Hydraulic actuators can be further classified as:

Tie-Rod Cylinder / Welded Cylinder:

Sturdy structure, suitable for high-pressure, heavy-load industrial applications.

Piston Rod Cylinder:

The most common type, transferring thrust through a piston rod, customizable in stroke and diameter.

Adjustable Stroke Cylinder:

Allows adjustment of maximum stroke as required, adapting flexibly to different working environments.

Locking Cylinder:

With mechanical locking, used for load holding or safety protection.

3.Pneumatic Linear Actuator

A pneumatic actuator uses Compressed Air to push pistons or rods, enabling fast, reciprocating linear motion. To highlight application characteristics, pneumatic actuators can be classified by structure and motion:

Rodless Cylinder:

The piston drives the load directly through magnetic force or a slider, suitable for long-stroke, space-constrained scenarios.

Guided Cylinder / Guided Rod Cylinder:

With guide rods or sliders to ensure smooth motion, suitable for applications with large lateral forces.

Compact Cylinder / Mini Cylinder:

Small and lightweight, suitable for light-load, space-limited automation equipment.

4.Advantages of Electric Linear Actuators

In modern Industrial Automation, Robotics Systems, and Smart Devices, Electric Linear Actuators are gradually replacing traditional Hydraulic Actuators and Pneumatic Actuators due to their multiple advantages.

High Precision and Repeatability

Electric actuators, driven by servo motors or stepper motors, utilize lead screws / ball screws or rack-and-pinion mechanisms. Combined with position sensors and closed-loop control, they can achieve micron-level positioning accuracy and repeatability, making them ideal for precision assembly, semiconductor manufacturing, and high-accuracy measurement equipment. In contrast, hydraulic and pneumatic systems are limited in positioning accuracy and repeatability due to the compressibility of fluids or gases and pipeline delays.

Programmable and Intelligent Control

Electric actuators are easy to integrate with PLCs, DCS, or Industrial Ethernet, enabling software-based control of stroke, velocity, acceleration, and torque. Users can quickly adjust motion parameters to achieve complex motion profiles and intelligent operation. By comparison, hydraulic or pneumatic actuators typically rely on mechanical valve adjustments or proportional valves, which offer limited flexibility and response precision.

High Energy Efficiency and Low Maintenance

Electric actuators directly convert electrical energy into mechanical energy with efficiencies of over 80%. They require neither hydraulic oil nor compressed air, resulting in lower energy consumption and simpler maintenance. Hydraulic systems depend on pumps, pipelines, and hydraulic fluids, which introduce energy losses and leakage risks. Pneumatic systems are limited by the low efficiency of compressed air and lead to higher long-term operating costs. In contrast, electric systems are not only energy-saving but also reduce maintenance frequency and downtime costs.

Environmental Adaptability

Electric actuators eliminate the risks of hydraulic oil leakage or gas leakage, making them suitable for environments with strict cleanliness requirements such as cleanrooms, medical devices, and food processing. Furthermore, with proper IP-rated protection, actuators can withstand humid, dusty, or corrosive environments, ensuring long-term stable operation.

Dynamic Response and Controllable Force

With the support of high-performance motors and motor drivers/servo drives, electric actuators deliver high dynamic response, precise force/thrust control, and customizable velocity profiles. This makes them well-suited for high-frequency reciprocation, precision positioning, and complex trajectory movements. In contrast, hydraulic and pneumatic systems are constrained by inertia and fluid compressibility, which limit their response speed and force control capabilities.

5. How to Choose the Right Linear Actuator

Selecting the right Linear Actuator is essential to ensure the efficient and reliable operation of a mechanical system. Different types of actuators vary significantly in thrust, stroke, speed, accuracy, and control methods, so multiple factors need to be considered during the selection process.

Thrust and Load Capacity

The first step is to define the mechanical load and the required thrust. Electric Linear Actuators, powered by servo motors or stepper motors, can deliver precise thrust, making them suitable for medium-to-light loads and high-precision positioning. Hydraulic Linear Actuators can provide very high thrust, making them ideal for heavy loads and continuous-duty applications. Pneumatic Linear Actuators are best suited for lightweight loads and fast reciprocating motion.

When selecting, the actuator’s maximum thrust should be higher than the required load capacity, with an additional 20–30% safety margin to ensure long-term stability. For applications requiring higher thrust or heavy-load handling—such as medical bed adjustment, heavy industrial equipment, or high-load automation systems—a high-thrust electric actuator like Jiecang JC35B8 is a suitable choice. It can deliver up to 6,000N of powerful thrust while maintaining a compact design and high protection rating, ensuring stable performance even in demanding environments.

Stroke and Velocity

The stroke length of an actuator determines the maximum travel range of the load. Electric actuators are well-suited for precise positioning, though their speed may be limited over longer strokes. Hydraulic and pneumatic actuators, on the other hand, can achieve high-speed, long-stroke movements, making them suitable for production line handling or automated assembly. Speed requirements should be evaluated based on the application: high-frequency reciprocating operations demand fast dynamic response, while precision assembly or positioning tasks emphasize stability and smoothness.

Precision and Repeatability

Applications requiring high accuracy place strict demands on positioning precision. Electric actuators, equipped with closed-loop control and position sensors, can achieve micron-level accuracy and excellent repeatability, making them ideal for robotic arms, semiconductor equipment, or laboratory platforms. In contrast, hydraulic and pneumatic actuators are inherently limited in positioning precision and repeatability due to the compressibility of fluids and gases.

In such high-precision environments, the Jiecang JC35W5 demonstrates significant advantages. It features a built-in electronic limit switch and an optional dual Hall sensor feedback system, ensuring precise positioning and repeatable operation during push rod extension and retraction. These capabilities make the JC35W5 an outstanding choice for applications that demand precise control, such as medical bed adjustment, smart furniture lifting systems, and precision handling in industrial automation.

Control Method

The choice of control method should align with the requirements of the automation system. Electric actuators can be easily integrated with PLCs (Programmable Logic Controllers), DCS (Distributed Control Systems), or Industrial Ethernet, enabling fully programmable control of stroke, speed, acceleration, and torque. By contrast, hydraulic and pneumatic actuators usually rely on proportional valves or mechanical adjustment devices, offering relatively lower flexibility.

Operating Environment and IP Rating

Environmental conditions have a direct impact on actuator lifespan. Electric actuators can be designed with different IP ratings, making them suitable for humid, dusty, or corrosive environments. Hydraulic systems must prevent oil leakage, while pneumatic systems depend on clean, stable air supply. For extreme conditions—such as high temperatures, humidity, or vibration—actuators with enhanced environmental resistance should be prioritized.

Energy Efficiency and Maintenance

Electric actuators convert electrical energy directly into mechanical energy, achieving high efficiency (>80%) with low maintenance requirements. Hydraulic systems require regular oil replacement and pump station monitoring, while pneumatic systems suffer from energy losses due to air leaks, leading to higher overall consumption. Depending on equipment usage frequency and maintenance capacity, selecting an energy-efficient and stable solution is essential.

Cost and ROI

Beyond performance, economic factors must be considered, including initial investment, installation costs, and long-term operating expenses. While electric actuators typically have a higher upfront cost, their high efficiency and low maintenance result in reduced operating costs over time. In contrast, hydraulic and pneumatic systems may offer lower initial costs but entail higher long-term expenses due to energy consumption and maintenance. Calculating return on investment (ROI) helps determine the most cost-effective solution.

Solar Powered

Solar-powered systems often operate with limited voltage and current, so actuators must deliver high energy efficiency and maintain thrust output and precise positioning under low-power conditions. This makes electric linear actuators far more suitable than hydraulic or pneumatic systems, as hydraulics require pump stations and pneumatics depend on compressed air—both impractical for standalone solar systems.

Against this backdrop, the Jiecang JC35SA16 was developed. Specifically designed for solar applications, this high-performance electric linear actuator combines high load capacity with outstanding weather resistance. It is widely used in photovoltaic tracking systems, smart shading devices, and other automation scenarios requiring high IP protection and precise motion control.

6. Categories of Electric Linear Actuators

By Supply Voltage

Low Voltage Actuators: Typically operating at 12V or 24V DC, these actuators are widely used in solar systems, smart furniture, and medical devices. They are characterized by high safety, easy installation, and reliable performance.

A representative product in this category is the Jiecang JC35FA8, which supports 12V or 24V DC input and delivers a thrust range of 120–1,500N. It comes with optional Hall sensor feedback or a potentiometer for precise positioning, while its IP66 protection rating ensures stable operation even in humid or dusty environments. This makes the JC35FA8 particularly well-suited for applications such as medical beds, nursing equipment, and smart furniture systems.

High Voltage ActuatorsHigh Voltage Actuators (e.g., 110V or 220V AC) are designed for industrial automation, heavy-duty machinery, and large-scale control systems, and can be powered directly from the mains supply.

By Stroke Length

Short Stroke Actuators: When installation space is limited or only a short stroke is required, a Short Stroke Actuator becomes the ideal choice. Typically featuring strokes under 100mm, these actuators are well-suited for precision adjustments and compact layouts.

A typical example is the Jiecang JC35FA21, which offers a customizable stroke range of 50–170mm, supports a load capacity of 1–3kN, and integrates Hall sensor feedback for precise positioning. With its IP67 protection rating, the JC35FA21 ensures reliable performance in demanding environments, making it an excellent fit for medical equipment, smart furniture, and industrial automation applications where space is restricted.

Medium/Long Stroke ActuatorsMedium/Long Stroke Actuators offer strokes up to 400mm or longer, making them ideal for solar photovoltaic tracking systems, height-adjustable desks, and industrial automation applications.

Telescopic or Multi-Stage Actuators

Telescopic or Multi-Stage Actuators feature a multi-section rod design that allows for long strokes within limited installation spaces. They are commonly used in medical beds, automatic doors, and adjustable devices.

By Mounting Method

Rod-End Mounting:

The actuator connects to the load through the rod end, suitable for pushing, pulling, or lifting operations.

Base Mounting:

The actuator body is fixed via the base, ideal for stationary linear driving applications.

Clamp / Rail Mounting:

Used in guided precision positioning or rail-based systems, enhancing stability in linear motion.

By Functional Features

Precision Actuators:

Equipped with closed-loop control, Hall sensors, or potentiometers, suitable for robotics, medical devices, and semiconductor equipment.

High Thrust Actuators:

Capable of delivering 3,000–6,000N or higher thrust, ideal for heavy-duty industrial machinery and medical beds.

Low Noise Actuators:

With noise levels of ≤50dB, these actuators are suitable for home, office, or medical environments.

A representative model is the Jiecang JC35L29 Electric Linear Actuator, designed for applications requiring quiet and reliable operation. It operates with minimal noise, delivering smooth performance without disturbing the user experience. The JC35L29 supports 24 V input, provides up to 8,000 N dynamic thrust and 4,000 N static pull, and has a maximum IPX6 protection rating, ensuring reliable performance in humid or dusty environments. Its stroke ranges from 50 mm to 250 mm, and optional feedback systems enhance positioning accuracy and operational reliability.

Outdoor or IP-Rated Actuators

Outdoor or IP-Rated Actuators feature protection against water, dust, and corrosion (e.g., IP65, IP66, IP67), making them suitable for solar tracking systems and other outdoor automation applications.

7. Installation Methods and Safety Guidelines for Linear Actuators

Installation Steps

Identify the Mounting Type

Before installation, choose the appropriate mounting method based on the application. Rod-end mounting is suitable for push/pull or lifting operations (e.g., hospital beds or smart furniture), while base mounting is ideal for stationary applications in industrial automation. The correct installation method is critical to ensuring stability and actuator lifespan.

Prepare Fasteners

Select bolts, nuts, or pins that match the actuator’s mounting holes. For high-load or long-stroke applications, use high-strength bolts or thread-locking agents to prevent loosening due to vibration.Secure Mounting Support

Ensure the mounting surface is flat and rigid. For long-stroke or heavy-duty actuators, add a guide rail or support rod to absorb side loads, reduce wear, and extend actuator life.Allow for Safety Clearance

Leave a buffer or mechanical stop at the stroke end to avoid collisions. A clearance of about 1–2mm is recommended to accommodate thermal expansion or slight misalignments.Connect the Load

Align the actuator rod or base with the load axis to prevent side loads. For heavy-duty applications, use a ball joint or universal joint to further reduce side force.Electrical and Control Connections

Follow the wiring manual strictly to ensure stable power and signal transmission. For actuators with feedback (e.g., Hall sensors, potentiometers), ensure secure and well-protected connections.Commissioning and Testing

Perform a no-load test first, checking for smooth extension/retraction without abnormal noise or vibration. Then test under load, ensuring limit switches or closed-loop feedback operate correctly.Key Notes

Ensure flat and solid mounting surfaces.

Use fasteners with sufficient strength and apply thread lock if needed.

Add guide rails/supports for long-stroke or high-load use.

Keep the load aligned with the actuator axis.

Leave buffer space at stroke ends.

Ensure correct and stable wiring.

Test unloaded before full-load operation.

Safety Tips

Never exceed rated thrust or load capacity.

Use IP65/IP66/IP67-rated actuators in humid or outdoor environments.

Avoid side loads to prevent bending and uneven wear.

Perform regular inspections of fasteners, guides, and feedback systems.

8. Case Studies and Industry Applications

After understanding actuator principles, classifications, precision, and thrust characteristics, it’s clear that different industries have unique requirements: some prioritize low-voltage safety and quiet operation, while others demand high thrust and long stroke. Below are four representative application fields:

Smart Office Industry Applications

In modern workplaces, linear actuators are widely used in height-adjustable desks, electric lift conference tables, and multi-functional workstations. With low-noise and high-precision actuators, desks can move smoothly while meeting ergonomic design standards.

Typical Applications:

Employees can switch easily between sitting and standing positions.

Conference tables can be quickly adjusted for different scenarios.

Advantages and Selection Tips:

Use 12V/24V DC low-voltage actuators for safety.

Low-noise designs (≤50dB) maintain a quiet work environment.

Optional Hall sensors or potentiometers enable precise position control and synchronized lifting.

Healthcare Industry Applications

In healthcare, actuators are used in electric hospital beds, nursing beds, operating tables, and rehabilitation devices. These applications demand high thrust, precise positioning, and reliability.

Typical Applications:

Hospital beds adjust head and leg angles to improve patient comfort.

Rehabilitation devices assist with controlled linear motion for therapy.

Advantages and Selection Tips:

Choose actuators with IP66/IP67 protection for hospital environments.

High-thrust models (e.g., JC35B8) support patient weight and bed loads.

Closed-loop control ensures micron-level accuracy and repeatability.

Low-noise performance creates a quiet medical environment.

A notable case is the Infant Incubator, where actuators play a critical role. The incubator provides premature or underweight babies with a warm, humid, and stable environment. Linear actuators precisely control temperature, humidity, and oxygen concentration, ensuring optimal growth conditions.

For example, the Jiecang JC35W10 Electric Linear Actuator is widely used in incubators. With high thrust and robust protection, it ensures stable operation under demanding conditions. Its precise positioning enables accurate parameter adjustments, directly enhancing neonatal care quality. Additionally, actuators can adjust incubator height and angle, facilitating caregiver access. The low-noise and low-power consumption further improve usability and safety.

Smart Home Industry Applications

In smart home applications, linear actuators are mainly used in automated curtains, liftable TVs, adjustable beds, and multifunctional furniture. By enabling electric-driven motion, they optimize space usage and bring automation to daily living, making life more convenient and comfortable.

Typical Applications:

Automated curtains that open or close based on lighting or time, saving energy while ensuring privacy.

Liftable TVs or hidden furniture that can be stored when not in use, enhancing safety and aesthetics of living spaces.

Advantages and Selection Tips:

Low-voltage actuators ensure safety in household environments, reducing the risk of electric shock.

Short-stroke actuators are ideal for space-constrained furniture designs.

Low-noise operation makes them particularly suitable for bedrooms or living rooms.

Can be integrated with smart control systems for remote or automated operation.

Industrial Automation Industry Applications

In industrial automation, linear actuators focus on high thrust, long service life, and high precision. They are widely applied in automated production lines, assembly equipment, logistics handling systems, and solar tracking.

Typical Applications:

Push–pull or lifting actions on automated production lines to improve assembly efficiency.

Logistics and material handling systems for moving or sorting goods.

Solar tracking systems that adjust panel angles to maximize energy output.

Advantages and Selection Tips:

High-thrust actuators support heavy-duty operations.

Long-stroke or telescopic actuators are suitable for large-scale movements.

Closed-loop control and sensor integration enable precise positioning and repeatability.

High IP-rated protection (IP66/IP67) ensures durability in outdoor, humid, or dusty environments.

Application in Agricultural Machinery

With the rapid development of agricultural mechanization, linear actuators have become a key technology for improving precision farming and operational efficiency in fertilizer spreaders. These machines, used to evenly distribute fertilizer, directly affect crop growth and soil quality. Traditional spreading methods often rely on manual operation, leading to uneven distribution, fertilizer waste, and environmental concerns. The adoption of linear actuators provides a higher degree of automation and precision control.

Key Roles of Linear Actuators in Fertilizer Spreaders:

Precise Fertilizer Control: By accurately adjusting the opening of the spreading discs, actuators regulate the amount of fertilizer dispensed, minimizing waste.(e.g.,JC35FA32)

Automated Operation: Integrated with GPS and task data, actuators automatically adjust spreading width and angle, improving precision and efficiency.

Enhanced Productivity: Automated control systems reduce manual labor, improving consistency and overall field operation efficiency.

9. Why Choose JIECANG?

Since our establishment in 2000, we have been dedicated to the research, development, manufacturing, and sales of linear drive systems. With continuous innovation and deep technical expertise, we have obtained more than 900 patents, covering core technologies such as motor noise control, gear transmission, and stroke control. Our three RandD centers and over 500 engineers collaborate with leading universities, including Shanghai Jiao Tong University and Zhejiang University, driving technological advancement and delivering high-performance, reliable linear actuator solutions for diverse applications.

On the manufacturing and supply side, we have built a global production and service network, with nine production bases located in China, the United States, Malaysia, the Czech Republic, Austria, and other regions. Equipped with advanced facilities such as automated cutting lines, robotic laser systems, and powder-coating lines, our network ensures efficient delivery and consistent product quality. Our operations are certified under ISO9001, ISO14001, and ISO/IEC27001, while our products hold multiple international certifications, including UL, CE, RoHS, SAA, PSE, and KC, meeting the varied requirements of global markets.

Thanks to our reliable products and extensive service network, we have earned the trust of world-renowned companies such as Google, Microsoft, Apple, and Amazon. Our actuators are widely used in smart office, medical care, and home automation applications. With subsidiaries in the United States, Germany, Japan, India, and beyond, we provide timely technical support and after-sales service, while also seeking to collaborate with more partners to ensure project success.

Conclusion

Linear actuators are an indispensable component of modern technology and automation systems, driving precise movements and mechanical operations. By understanding the different types of actuators, their key parameters, and how to select the right model, users can optimize performance and meet the unique requirements of their applications.

We hope that in exploring linear actuators, you find the same depth and excitement that we do—especially when choosing the most suitable actuator for your projects. If you have any questions or face challenges in selecting the right actuator, please feel free to reach out to us. With our expertise and experience, we are ready to provide professional guidance and support to help your applications succeed.

Linear Actuator FAQ

1. What is the typical operating noise of a linear actuator?

Operating noise depends on the drive type and internal transmission system. High-quality electric actuators usually operate below 50 dB under no-load conditions, making them suitable for noise-sensitive environments.

2. Can linear actuators operate in extreme environments?

Yes. Some actuators are designed to withstand high/low temperatures, humidity, or dusty environments. Their protection level (e.g., IP54, IP65) can be selected to ensure long-term reliable performance.

3. Do linear actuators support feedback control?

Yes. Many actuators are equipped with position sensors or encoders, enabling closed-loop control for precise positioning and motion accuracy, ideal for complex automation systems.

4. How can I extend the service life of a linear actuator?

Perform regular inspections of drive components, guides, and lubrication systems. Keep the environment clean, avoid overload conditions, and ensure proper maintenance to significantly extend service life.

5. What are the common installation methods for linear actuators?

Mounting options include base mounting, side mounting, or front/rear support mounting. The choice depends on space constraints and load requirements, ensuring stable and safe motion.

QUICK LINKS