- Home

-

- TF Integrated Workstation

- TT Integrated Station

- TS Single-Person Station

- TO Single-Person Station

- Advanced Office Table

- Manager Table

- Odette Conference Table

- Lifting White Board

- Lifting Podium

- Working Port

- Zen Standing Desk

- Lifting Coffee Table

- Home Standing Desk

- Nature Standing Desk

- Invictus Gaming Desk

- Study Desk

-

-

- Electric Hospital Bed

- Image Equipment

- Examination Bed/Clinic Bed

- Operation Table and Chair

- Infant Incubator

- Independent Weighing System

- Home Care Bed

- Patient Lift

- Wheelchair

- Toilet Lift

- Bath Lift

- Shower Trolley

- Smart Rollator

- Ophthalmic Workstation

- Treatment Chair

- Facial Chair

- Traction Table

- Massage Chair

- OT Training Equipment

- Stand-up Application

- Rehabilitation Robot

-

-

- Photovoltaic Application

- Photothermal Application

- Energy Storage Container

- Tractor

- Seeder

- Fertilizer Spreader

- Harvester

- Rotary Cultivator

- Climate Control System

- Automatic Feeding System

- Excavator

- High Altitude Work Platform

- Garbage Truck

- Street Sweeper

- AMR Automated Guided Vehicle (AGV) and Autonomous Mobile Robot (AMR)

- Forklift Accessories

- Palletizing Collaborative Robots

- Packaging Machine

- Mobile Light Tower

-

-

Linear Actuator Definition Principles and Types Guide

Views: 0 Author: Site Editor Publish Time: 2025-12-02 Origin: Site

What is a Linear Actuator?

A linear actuator is a mechanical device that converts electrical, hydraulic, or pneumatic energy into linear motion. Simply put, its function is to "push or pull" an object, causing it to move along a straight line, rather than rotating.

It is commonly used in smart homes, mechanical equipment, medical devices, and industrial automation, and is a core component that works silently in many modern devices.

Analysis of the Working Principle of Linear Actuators

How do linear actuators work? (Taking an electric type as an example)

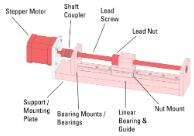

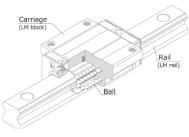

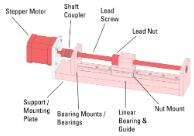

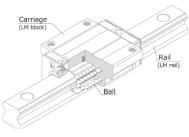

An electric linear actuator typically consists of a motor, a reducer, a lead screw, and a slider/push rod.

Operation process: The motor is powered on and rotates. The reducer then decreases the speed and increases the torque. At this point, the lead screw begins to rotate, and the slider or push rod begins to move linearly along the guide rail, completing actions such as pushing, pulling, lifting, and lowering.

Its actions can achieve: high positioning accuracy; support for intelligent control: such as automation via an app, remote control, or scene modes.

Common Types of Linear Actuators

1. Electric Linear Actuator: The most common type, using a motor to drive a lead screw or gear to achieve linear motion.

Advantages: Low noise, precise control, low maintenance, supports intelligent control.

Applications: Smart homes, medical equipment, industrial automation, etc.

2. Pneumatic Linear Actuator: Uses compressed air to drive a piston.

Advantages: High speed, simple structure, low cost.

Applications: Automated production lines, fixtures, light-duty industrial equipment.

3. Hydraulic Linear Actuator: Uses hydraulic oil to drive a piston, possessing powerful force.

Advantages: High thrust, suitable for heavy loads.

Applications: Construction machinery, heavy equipment, lifting platforms.

Linear Actuator VS Linear Actuator System

Linear Actuator

Linear Actuator System

As shown in the figure

Definition

Single device providing linear motion

A complete system consisting of multiple actuators and control systems.

Function

Completes a single push-pull task

Supports complex control and feedback, typically involving the coordinated operation of multiple actuators.

Components

Motor, lead screw/gear, push rod, etc.

Actuators, power supplies, controllers, sensors, etc.

Application Scope

Simple control tasks, such as lifting doors, curtains, etc.

Systems requiring coordinated and precise control of multiple actuators, such as automated production lines and robots.

Complexity

Relatively simple structure

Complex structure, involving the coordination of multiple subsystems

How to Choose a Suitable Linear Actuator?

There are three main types of actuators: pneumatic actuators (using compressed air), hydraulic actuators (using pressurized oil), and electric actuators. To help you choose the right actuator, we recommend considering several factors. (Taking electric linear actuators as an example)

Electric actuators, with their advantages of high precision, environmental friendliness, and low maintenance costs, are suitable for various fields such as home, industry, medical, and agriculture. They provide stable and reliable motion control, reduce manual intervention, and improve efficiency and safety. With increasing automation, the application scenarios for electric actuators will become increasingly widespread, becoming an indispensable part of future intelligent systems.

1. High Precision and Controllability

Electric actuators achieve high-precision linear motion and precise control by precisely adjusting position and speed through a motor and control system. Compared to traditional hydraulic or pneumatic actuators, electric actuators offer better precision and controllability, making them suitable for applications requiring precise operation.

2. Energy Saving and Environmental Protection

Electric actuators are driven by electricity, avoiding the problem of oil leakage in hydraulic systems and reducing environmental pollution. Furthermore, electric actuators have high working efficiency and can automatically adjust power according to the load, further improving energy efficiency. 3. Easy Installation and Low Maintenance

Compared to hydraulic and pneumatic actuators, electric actuators have a simpler structure, making installation and commissioning easier. Furthermore, electric actuators require less frequent maintenance. For example, hydraulic systems require regular oil changes, and pneumatic systems require inspection of the air supply and piping. Electric actuators have significantly lower maintenance requirements.

4. High Efficiency and Repeatability

Electric actuators can provide constant motion speed and load capacity, ensuring repeatability and consistency in each operation. This is crucial for industrial and automation scenarios requiring high-precision operation.

Regarding JIECANG Linear Actuators

JIECANG offers a wide range of electric linear actuators designed to meet the diverse needs of various industries. Some of the electric linear actuators in JIECANG's product line include:

The JC35L82 linear actuator is a low-noise, compact linear actuator designed specifically for smart home applications, offering greater flexibility for integrated home solutions. It is ideal for a variety of applications, including smart recliners, home theater chairs, massage chairs, and foot bath chairs.

The JC35D4 linear actuator is widely used in nursing beds, hospital beds, operating tables, and home care beds, thanks to its durability and wide range of specifications. This product features a robust construction, a thrust of up to 6000N, and meets the IP54 waterproof rating required for medical applications.

The JC35L is a rail-mounted actuator whose nut slides along an aluminum profile. It features high load capacity and is widely used in sofas, massage chairs, and television lifting devices. The JC35L is available in the following specifications: JC35L-4000N, JC35L-3000N, JC35L-2000N, JC35L-1500N, JC35L-1000N, and JC35L-750N.

The Solar Linear Actuator JC35SA1 is designed for photovoltaic applications, powering solar panels to track sunlight and maximize solar energy utilization. In solar photovoltaic applications, optimizing energy efficiency is crucial to fully realizing the potential of solar energy.

CONCLUSION

Linear actuators, with their high precision, energy efficiency, and low maintenance, have become crucial driving components for automation across various industries. They effectively improve system efficiency, reduce manual intervention, and are widely adaptable to diverse working environments. With the continuous development of intelligent technologies, the application scenarios and functions of linear actuators will continue to expand, making them one of the core technologies in modern automation systems. Choosing the right linear actuator is crucial for system stability and performance.

Frequently Asked Questions about Linear Actuators

1.What is the difference between linear actuators and rotary actuators?

Linear actuators complete tasks through linear motion, while rotary actuators are driven by rotational movements. Linear actuators are suitable for scenarios requiring linear push and pull, such as lifting, pushing, and clamping; rotary actuators are used in applications requiring rotational movements, such as robot joints and valve switching.

2. How to choose the right linear actuator?

When selecting a linear actuator, the following factors need to be considered:

Load capacity: Ensure the actuator's thrust or pull force meets the load requirements.

Stroke length: Select an appropriate stroke range based on actual needs.

Speed: Select the appropriate speed based on application requirements. Thrust and speed are usually interrelated.

Operating Environment: Select the appropriate protection rating (IP rating) based on the operating environment (e.g., humidity, temperature, dust).

Control Method: Select the appropriate control method based on the application scenario, such as switch control, remote control, or intelligent control.

3. Does a linear actuator require maintenance?

Electric linear actuators generally do not require much maintenance; occasional checks of the motor and lead screw lubrication are sufficient. Hydraulic and pneumatic actuators require regular checks of the oil or air supply, and prevention of leaks. Regular inspection and cleaning can extend the actuator's lifespan and reduce malfunctions.

Related Articles

QUICK LINKS