- Home

-

- TF Integrated Workstation

- TT Integrated Station

- TS Single-Person Station

- TO Single-Person Station

- Advanced Office Table

- Manager Table

- Odette Conference Table

- Lifting White Board

- Lifting Podium

- Working Port

- Zen Standing Desk

- Lifting Coffee Table

- Home Standing Desk

- Nature Standing Desk

- Invictus Gaming Desk

- Study Desk

-

-

- Electric Hospital Bed

- Image Equipment

- Examination Bed/Clinic Bed

- Operation Table and Chair

- Infant Incubator

- Independent Weighing System

- Home Care Bed

- Patient Lift

- Wheelchair

- Toilet Lift

- Bath Lift

- Shower Trolley

- Smart Rollator

- Ophthalmic Workstation

- Treatment Chair

- Facial Chair

- Traction Table

- Massage Chair

- OT Training Equipment

- Stand-up Application

- Rehabilitation Robot

-

-

- Photovoltaic Application

- Photothermal Application

- Energy Storage Container

- Tractor

- Seeder

- Fertilizer Spreader

- Harvester

- Rotary Cultivator

- Climate Control System

- Automatic Feeding System

- Excavator

- High Altitude Work Platform

- Garbage Truck

- Street Sweeper

- AMR Automated Guided Vehicle (AGV) and Autonomous Mobile Robot (AMR)

- Forklift Accessories

- Palletizing Collaborative Robots

- Packaging Machine

- Mobile Light Tower

-

-

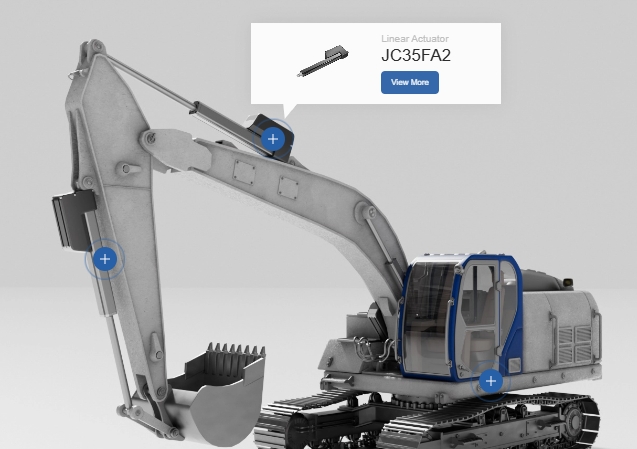

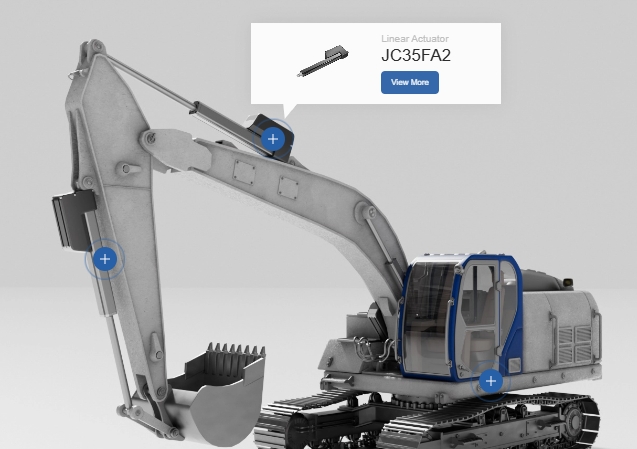

How Linear Actuators Are Revolutionizing the Excavator Industry?

Views: 0 Author: Site Editor Publish Time: 2025-07-10 Origin: Site

In the ever-evolving world of construction and earthmoving, excavators have become indispensable tools for projects ranging from roadwork to residential development. Today’s excavating contractors are not just looking for brute strength—they demand precision, efficiency, and intelligent control. This is where linear actuators are quietly but powerfully transforming the game.

Whether powering tilt mechanisms on mini excavator attachments or enhancing the precision of a Chinese mini excavator, these compact motion devices are critical to upgrading performance in modern machines. As top linear actuator manufacturers continue to refine technology for heavy machinery, including robust industrial linear actuator systems, excavator applications are entering a new era of automation.The following article will understand and explore the application and innovation of linear actuators in the excavator industry.

1. Why Industrial Linear Actuator Technology Matters for Heavy Equipment?

Industrial linear actuators stand out in heavy machinery for their ability to deliver precise motion without the complexity of hydraulics. Compared to hydraulic cylinders, electric actuators are:

Easier to install and maintain

Less prone to leakage

Programmable for smart automation

Solutions for industrial automation in excavators are built to handle high forces while maintaining compact dimensions. These actuators are crucial for smart excavation systems that integrate GPS, sensors, and real-time feedback for operator-assist functions.

2. Enhancing Control Systems with Linear Actuators in Excavators

Modern excavators rely on accurate movement to minimize errors and reduce fuel consumption. Linear actuators enable this by converting rotary motion into controlled, repeatable linear motion. In excavators, they can be used for:

Cabin comfort adjustment: Electric actuators control seat positioning and dashboard movement.

Boom and arm articulation support: Actuators assist with controlled depth adjustment and precise angle holding.

Maintenance automation: Opening engine covers or access hatches at the press of a button.

JIECANG’s customized industrial actuators are tailored for excavator environments, offering water resistance and high load-bearing capacity.Products like Electric Industrial Linear Actuators deliver IP66-rated protection and heavy-duty load capacity—ideal for use in rough outdoor construction zones.

3. The Rise of the Chinese Mini Excavator and its Integration with Actuator Tech

The Chinese mini excavator market has experienced tremendous growth due to competitive pricing and increased production quality. Many Chinese OEMs are now integrating advanced actuator technologies to meet global demands.

JIECANG collaborates with major Chinese equipment manufacturers to supply actuators that meet international safety and performance standards. These electric actuators help elevate the capabilities of mini excavators by providing:

Improved stability in narrow dig sites

Automated boom positioning

Electrically driven maintenance features

This integration boosts the value of Chinese-built machines, making them viable in high-end markets like Europe and North America.

4. Smarter Mini Excavator Attachments Powered by Linear Actuators

Mini excavator attachments such as tilting buckets, hydraulic thumbs, and quick couplers can be greatly enhanced using linear actuators. These upgrades allow:

Remote-controlled precision for bucket angling

Safer, tool-less coupling of attachments

Automatic repositioning and alignment for repeat tasks

Electric actuators enable fine-tuned control for compact excavators, especially in urban or indoor environments.Using actuators from reliable linear actuator manufacturers ensures compatibility with rugged job site requirements, offering custom stroke lengths and feedback integration for smart systems.

5. Comparing Backhoe vs Excavator in Automation Capabilities

The debate of backhoe vs excavator continues in many construction circles, especially when considering automation upgrades.

Feature

Backhoe Loader

Excavator

Typical Use

Light to medium construction

Medium to heavy digging & demolition

Automation Integration

Moderate (usually limited)

High (suitable for smart actuators)

Best Fit for Actuators

Seat and bucket control systems

Boom, cab, and blade angle control

Because excavators are designed for more precise digging and repetitive motion cycles, they benefit more from the integration of linear actuator systems, especially in applications like grade control and automated depth adjustments.

6. What Excavating Contractors Should Know Before Adopting Linear Actuators

For today’s excavating contractor, adopting linear actuator systems can translate to higher operational efficiency and safer work environments. Key considerations before integration include:

Voltage compatibility (12V/24V options)

Load and stroke specifications

Environmental resistance (IP ratings for dust and water)

Support and customization from trusted linear actuator manufacturers

Choosing a provider like JIECANG offers customizable actuator solutions designed specifically for excavator integration, supporting smart control systems and rugged outdoor use. Ensuring that excavator automation is scalable and adaptable to various models and attachment types.

Conclusion

Whether automating a cab adjustment system or enhancing the control of mini excavator attachments, linear actuators have become a central component in excavator modernization. Their flexibility, precision, and durability make them ideal for integration into both large-scale and compact equipment.

For excavating contractors, especially those using or maintaining a Chinese mini excavator, the shift to smart actuator-powered components can significantly improve operational output and worker safety. As the debate between backhoe vs excavator continues, the latter clearly benefits more from this next-gen motion technology. To stay ahead in the competitive construction landscape, partnering with experienced linear actuator manufacturers ensures your excavator systems are prepared for the future of smart, automated excavation.

Linear Actuator FAQs:

1. How do industrial linear actuators compare to hydraulic systems in excavators?

Industrial linear actuators offer several advantages over hydraulic systems, including quieter operation, lower maintenance, and improved energy efficiency. They are especially suitable for modern smart excavators, where precision and integration with digital systems are essential.

2. Are linear actuators compatible with Chinese mini excavators?

Yes, many Chinese mini excavator manufacturers are now integrating linear actuators to enhance performance and automation. Leading linear actuator manufacturers like JIECANG offer customizable solutions specifically designed to meet the demands of compact excavator models produced in China.

3. What’s the difference between a backhoe and an excavator in terms of actuator usage?

While both machines can benefit from automation, excavators—especially those with advanced control systems—are generally more compatible with linear actuator integration. In the backhoe vs excavator comparison, excavators typically support a wider range of actuator-powered applications like boom articulation, attachment swapping, and GPS-guided digging.

Related Articles

QUICK LINKS