- Home

-

- TF Integrated Workstation

- TT Integrated Station

- TS Single-Person Station

- TO Single-Person Station

- Advanced Office Table

- Manager Table

- Odette Conference Table

- Lifting White Board

- Lifting Podium

- Working Port

- Zen Standing Desk

- Lifting Coffee Table

- Home Standing Desk

- Nature Standing Desk

- Invictus Gaming Desk

- Study Desk

-

-

- Electric Hospital Bed

- Image Equipment

- Examination Bed/Clinic Bed

- Operation Table and Chair

- Infant Incubator

- Independent Weighing System

- Home Care Bed

- Patient Lift

- Wheelchair

- Toilet Lift

- Bath Lift

- Shower Trolley

- Smart Rollator

- Ophthalmic Workstation

- Treatment Chair

- Facial Chair

- Traction Table

- Massage Chair

- OT Training Equipment

- Stand-up Application

- Rehabilitation Robot

-

-

- Photovoltaic Application

- Photothermal Application

- Energy Storage Container

- Tractor

- Seeder

- Fertilizer Spreader

- Harvester

- Rotary Cultivator

- Climate Control System

- Automatic Feeding System

- Excavator

- High Altitude Work Platform

- Garbage Truck

- Street Sweeper

- AMR Automated Guided Vehicle (AGV) and Autonomous Mobile Robot (AMR)

- Forklift Accessories

- Palletizing Collaborative Robots

- Packaging Machine

- Mobile Light Tower

-

-

JIECANG Showcases Core Drive Technology at 2025 Humanoid Robot Industry Conference – Empowering Dexterous Robot Motion

Views: 0 Author: Site Editor Publish Time: 2025-12-18 Origin: Site

From November 27 to 28, 2025, the "2025 Humanoid Robot Industry Conference & Humanoid Robot Joint Module Innovation Forum" was held in Hangzhou. Focusing on four core areas—complete machines and application scenarios, dexterous hands, sensors, and joint modules—the conference built a collaboration platform for industry, academia, research, and application. It attracted over 600 elites from the entire industrial chain, covering the full ecosystem from core components to application scenarios.

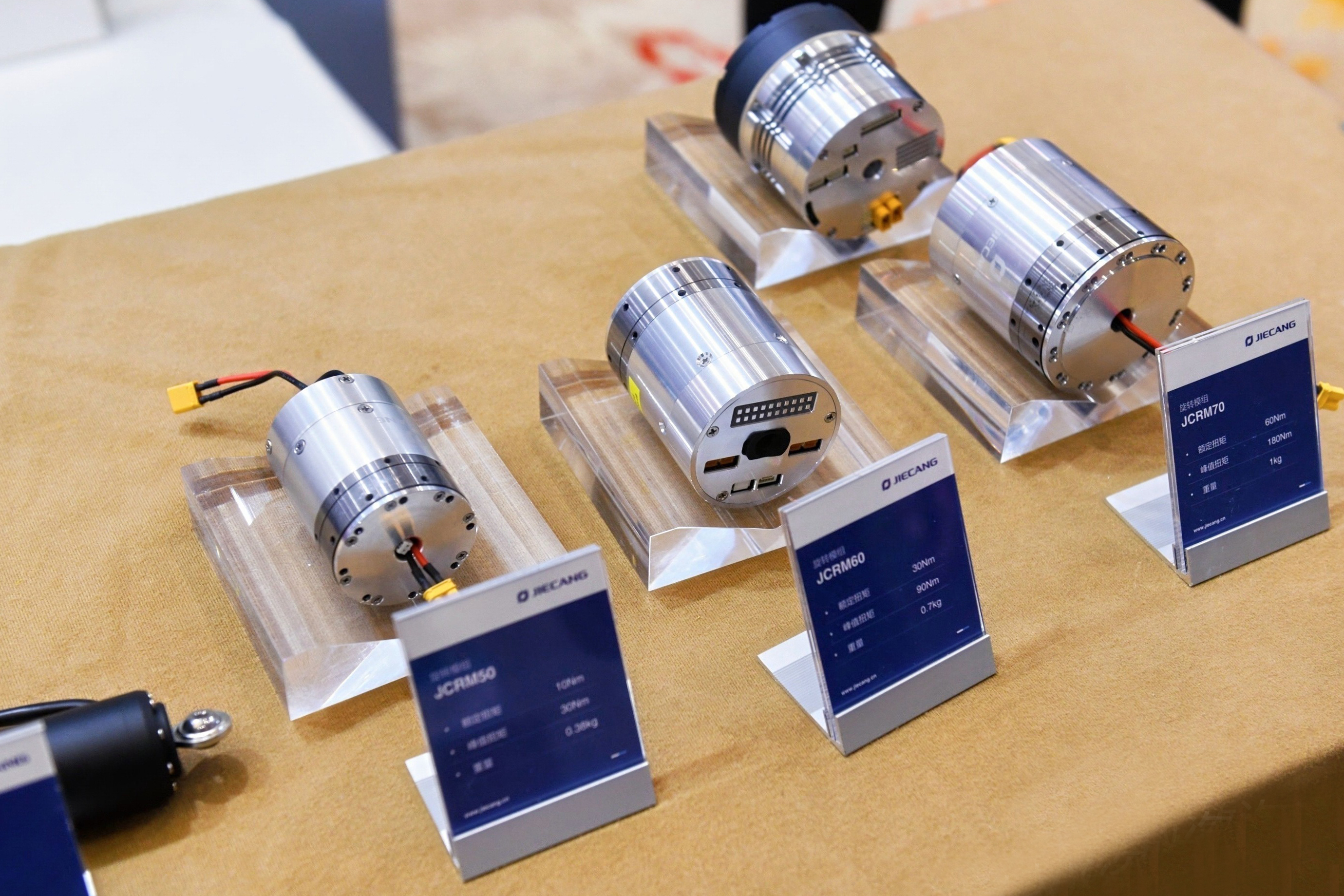

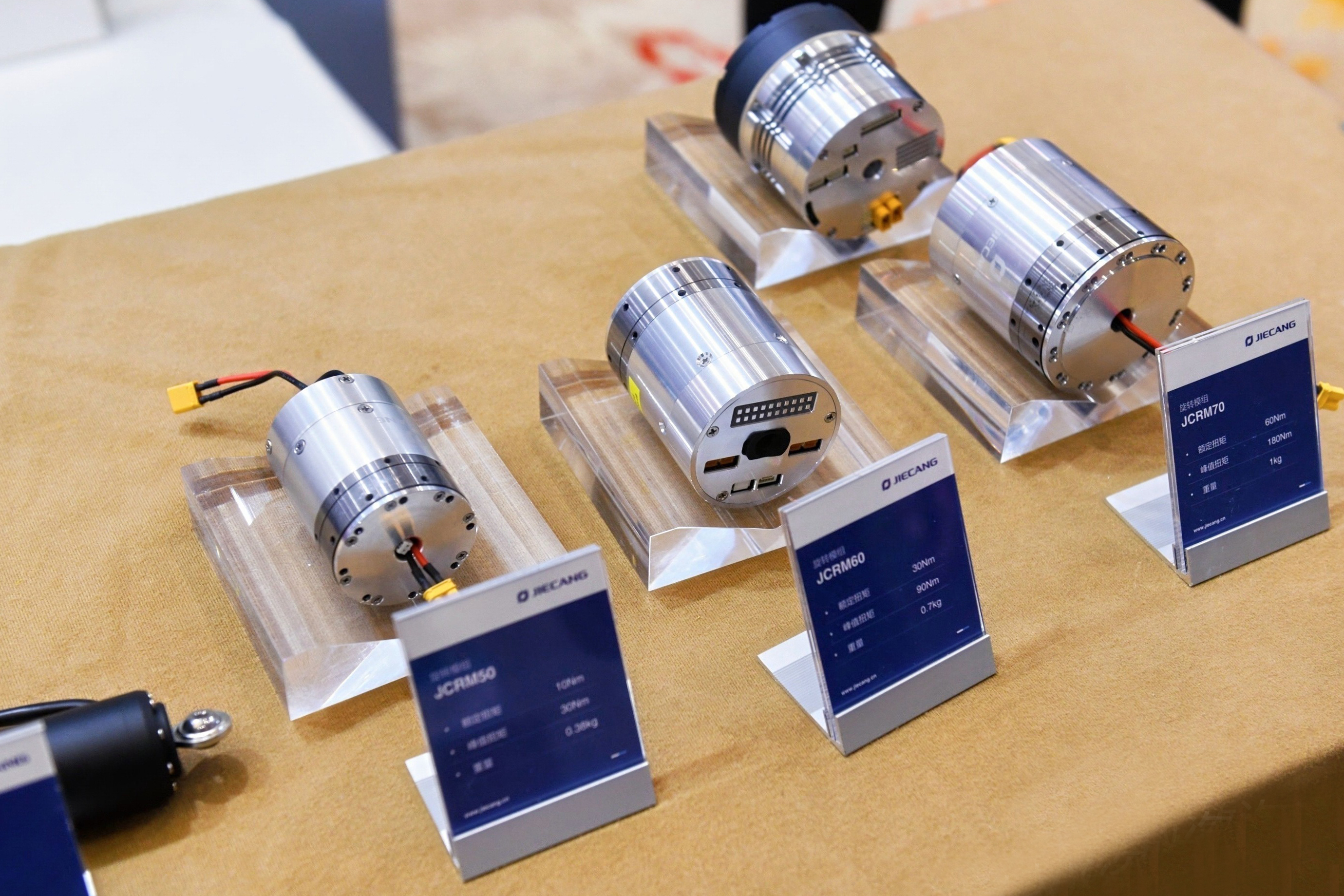

At this grand event, JIECANG — a "veteran" with 25 years of deep expertise in the linear motion field—showcased its latest innovations for the robot industry. Free from exaggerated conceptual hype, the booth displayed the "muscles" and "joints" that enable robots to achieve precise movement: coreless motor assemblies, rotary modules, and linear actuators. These core drive components are quietly becoming the key cornerstones driving the maturity of the humanoid robot industry.

From Linear Drive to Robot "Joints": A Powerful Technological Extension Built on Years of Accumulation

For many industry observers, JIECANG was known in this field. As a technology group with years of experience in motors, transmission systems, electronic control, and precision manufacturing, its products have been widely applied in smart office, smart home, medical care, industrial automation, automotive automation, and other fields. Its high-profile appearance at the Humanoid Robot Conference is not a simple cross-border expansion, but a natural extension of its technical heritage.

Based on its profound understanding of precision transmission and control accumulated over the years, JIECANG has established a dedicated Robot Actuator Business Center. This signifies that the company is systematically applying the know-how in precision, efficiency, and reliability gained from linear motion control to solve core motion challenges in robots—especially humanoid robots.

Independent R&D + Independent Manufacturing + Strict Quality Control: A Complete Closed Loop for Core Competitiveness

JIECANG deeply understands the decisive role of core components in the overall performance and reliability of robots. At the conference, the company's responsible person clearly elaborated on its core advantage: building a complete closed-loop system of "Deep Independent R&D + Independent Manufacturing + Strict Quality Control". This is not just a slogan, but the fundamental guarantee for its products to realize the core concepts of "high precision, high integration, modularization, and lightweight".

Independent R&D: Mastering the Lifeline of Core Technology

JIECANG refuses to be merely an assembler; instead, it delves into underlying technologies. It has mastered core technologies for key components such as dual-steel-wheel harmonic reducers, new-type harmonic reducers, reverse planetary roller screws, frameless torque motors, and brushless coreless motor assemblies. This means high technical autonomy from the power source to precision transmission, enabling the company to guarantee performance, optimize matching, and control costs from the source.

Independent Manufacturing: Forging Product Consistency and Reliability

More notably, JIECANG has established a complete vertical manufacturing system covering SMT assembly → precision machining → transmission component manufacturing → final assembly and testing. This full industrial chain, spanning circuits, precision processing, core transmission, and final assembly, ensures that every product leaving the factory possesses high consistency and excellent reliability, meeting the stringent requirements of the robot industry for batch stability of core components.

Strict Quality Control: Safeguarding Product Lifespan

Quality control is not just a final inspection process but runs through the entire lifecycle of R&D, manufacturing, and testing. JIECANG has established a rigorous quality control system, implementing strict inspections for every process and component, providing a solid guarantee for the long-term stable operation and service life of its products.

"High Precision, High Integration, Modularization, Lightweight": Tangible Achievements of Drive Technology

It is precisely based on the aforementioned closed-loop system that JIECANG 's exhibited products have achieved strong market competitiveness.

Coreless Motor Assemblies: The "Power Source" for Robots' Dexterous Hands

Its core advantages lie in high power density, fast response, and low inertia, providing strong and precise power for robot end effectors, finger joints, and other parts requiring compact and agile movement.

- Rotary Modules: The "Joints" of Robots Highly integrated with motors, reducers, encoders, and drivers, they realize modular joint movement. Developers no longer need to match components from scratch, but can obtain a plug-and-play, performance-optimized rotary motion unit—greatly simplifying the design and manufacturing process of robot bodies.

- Linear Actuators: The "Skeletal Muscles" of RobotsResponsible for converting rotary motion into precise linear motion, they are used for robot actions such as telescoping, pushing, pulling, and lifting. JIECANG has infused its years of technical advantages in linear motions into this product, striving for a better balance in thrust, speed, noise, and service life.

These components do not exist in isolation but can work synergistically to build a flexible, precise, and efficient foundation for motion control. For robot manufacturers, such a full-stack drive component solution means significantly shortened R&D cycles, reduced engineering complexity, and the ability to focus more on overall machine design, algorithm development, and scenario applications.

Empowering Industrial Upgrades: Being the "Driver" Behind Robots

At the critical stage when humanoid robots are moving from laboratories to commercial applications, the performance, cost, and reliability of core components are crucial. JIECANG's role is precisely that of a key "core component provider" in the industrial chain. The company does not directly manufacture robots, but is committed to providing robot makers with the highest-quality "motion units".

By participating in this industrial conference, JIECANG conducted in-depth exchanges and learning with industry peers. This atmosphere of collaborative progress is an essential condition for promoting the entire industry to break through bottlenecks and accelerate development. JIECANG stated that it will continue to focus on the independent R&D and production of core robot drive components in the future, contributing its solid strength to the upgrading and transformation of the robot industry with stable and efficient "driving" power.

As the robot era approaches, JIECANG enterprises that silently cultivate and continuously innovate in core fields that lay the solid foundation for the vigorous development of the entire industry.

Related Articles

QUICK LINKS